Research and Development

The company offers great value to its customers through innovation and sustained research in product performance enhancement.

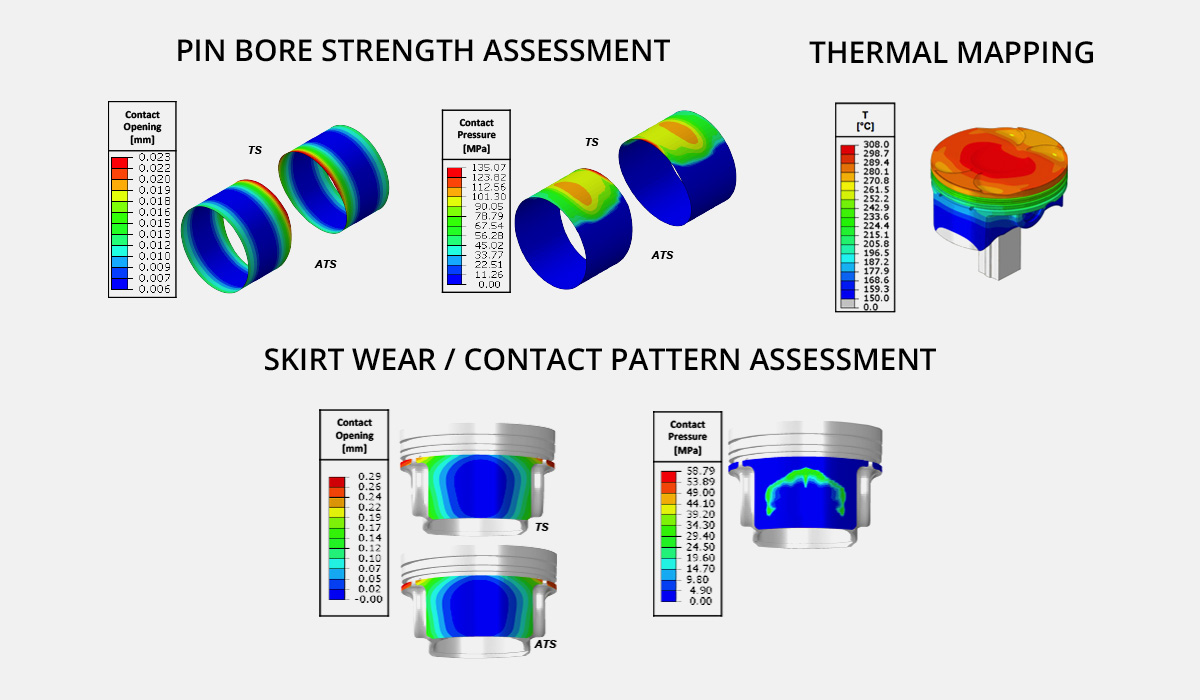

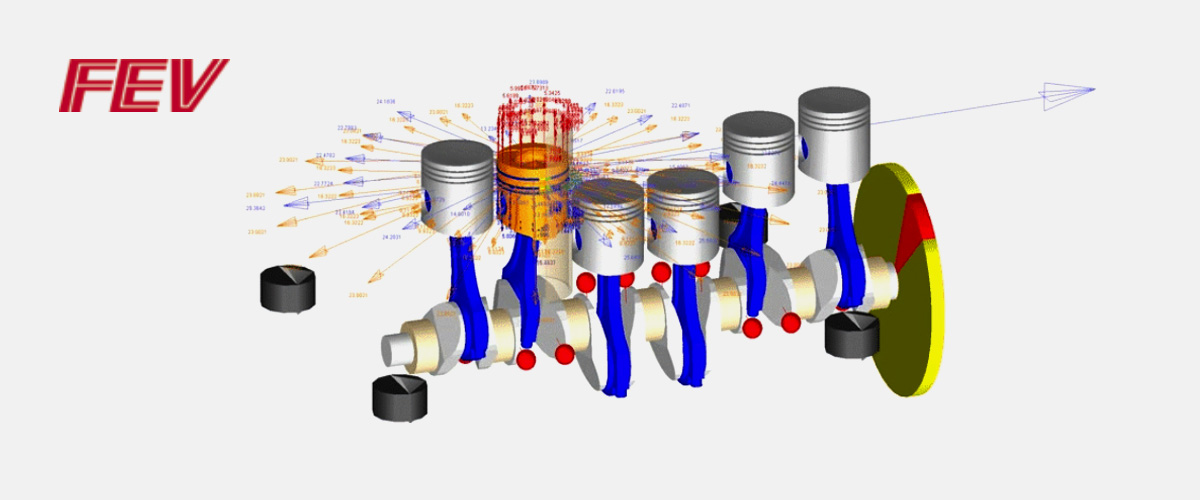

Advanced 3D Ring and Piston Simulation using FEV tools

IPL is the first one to introduce 3D Piston and Ring Dynamics against other competitors in India.

- Piston Secondary Motion & Ring Dynamics coupled for precise prediction of Blow-By / OC and Friction.

- Complex Wall pressure / Resultant Forces exerted on Ring Regimes can be evaluated

- 3D dynamic movement calculation of piston secondary motion for NVH REDUCTION

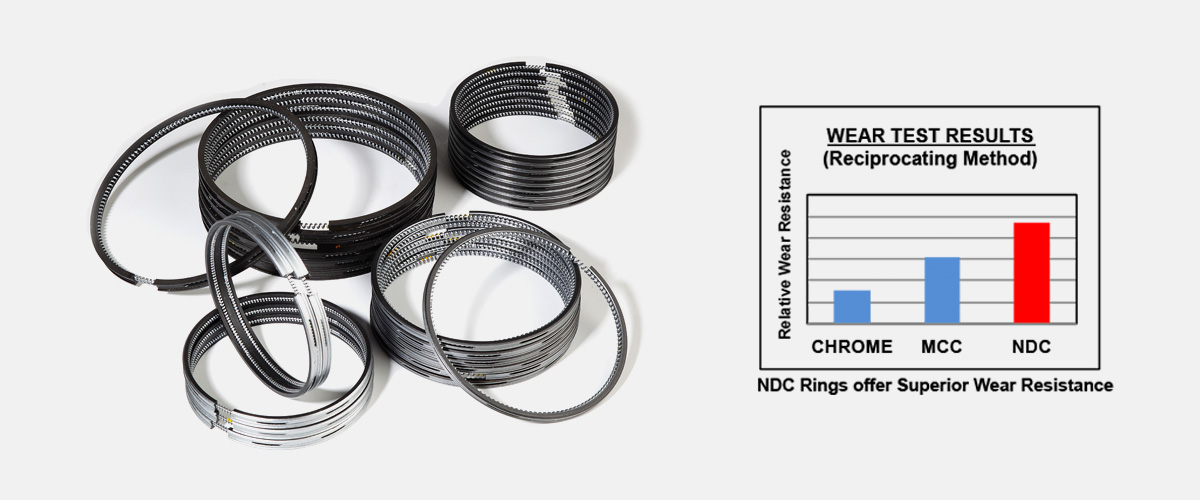

Range of Ring Surface Coatings

- Chrome plated

- Moly Sprayed

- Chrome Moly coated

- Moly Chrome Ceramic MCC (Patented)

- Nano Diamond Coated (NDC) (Patent Applied)

- PVD & GN

- Diamond Like Carbon (DLC)

State of Art Design Optimisation (DOE)

- Fe-safe – Fatigue Life Prediction

- Tosca – Tapology Shape Optimization for extreme weight reduction on piston assembly

- Isight – Design of Experiments (DOE).

Low Friction Piston Assembly solutions for BSIV & BSVI

- IP Lite & Ultralite Gasoline Pistons

- IP Low Friction HCV Pistons

- DLC Pin & Rings

- IP Glide – Special Oil Control Ring Profile